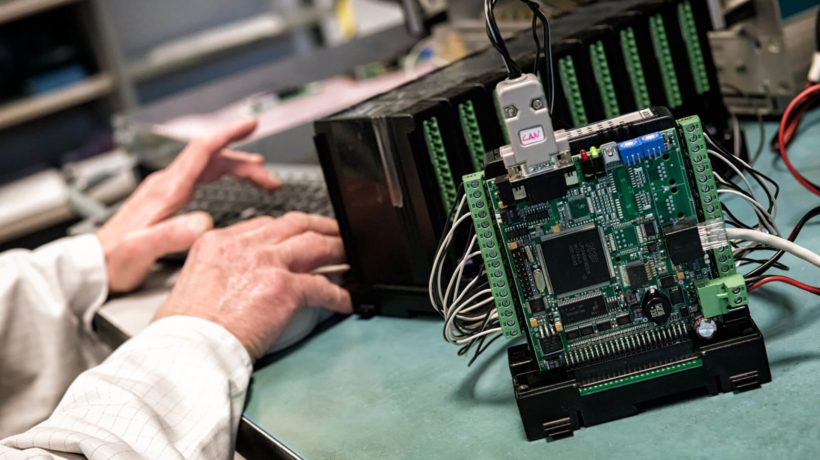

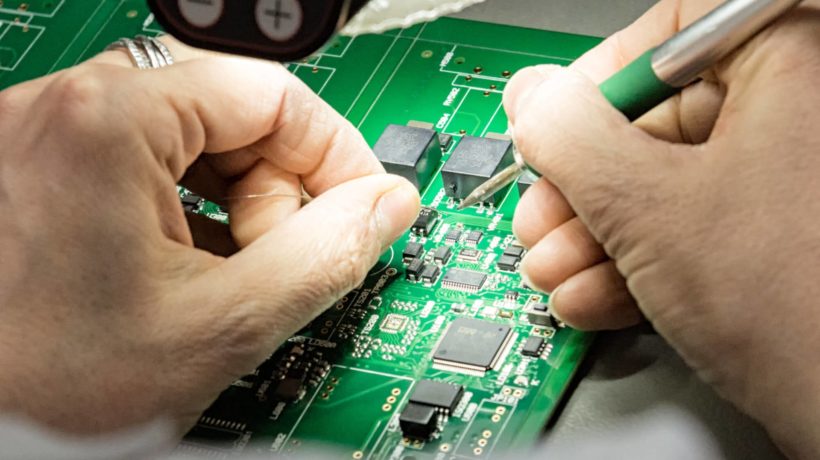

The production department, is an essential strength for Tecnint

Located in the Osnago headquarters, is structured to meet the various needs of the customer in terms of flexibility, efficiency and autonomy, in a professional and technological context in step with the times.

The production line, built according to the canons of industry 4.0, allows Tecnint the traceability and complete control of the entire production flow.

Tecnint’s choice to make use of its own internal electronic production line derives from the awareness of wanting to offer customers the guarantee of complete product quality, which starts from the choice of components and their conservation, passing from modern technologies and construction methods, up to final testing and functional tests, 100% realized on all cards.

The production line capability allows us to respond to requests of only electronic assembly, always complemented by functional tests and inspections, activities that distinguish Tecnint from the simple assembler / subcontractor

Main production phases

- Purchase and verification of components, stored in automated warehouses

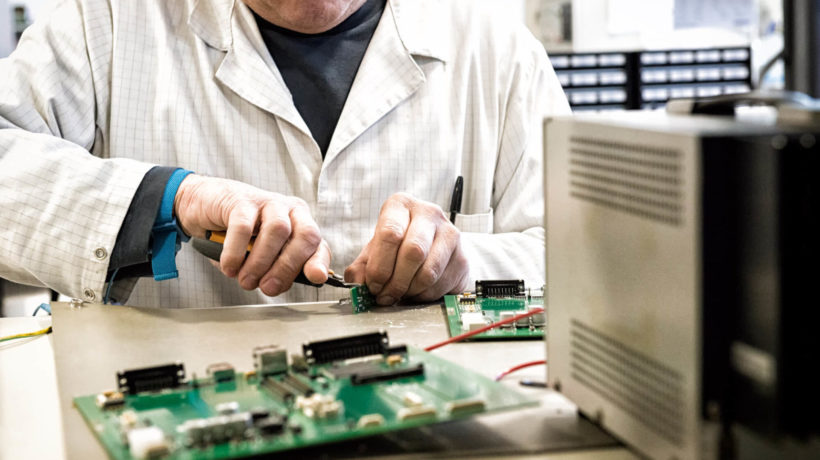

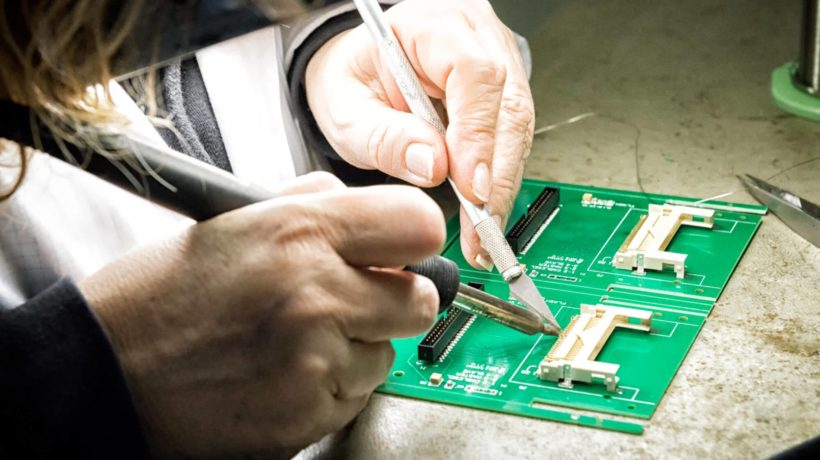

- Automated assembly and welding with SMD, THT and reworking of BGA components

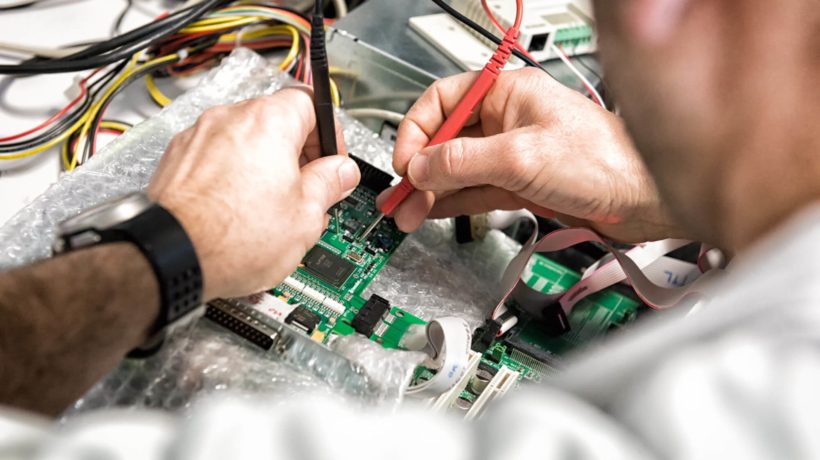

- Customized functional testing on each board and with the aid of automatic test benches. The test is carried out 100% on all cards and not on sampling.

- Possible conformal coating, selective or total, with automatic painting line

- Realization of finished products, with assembly of simple and / or complex mechanical parts

- Optical inspection with automatic detection of assembly and welding anomalies

- Environmental tests with BURN-IN cycles in a climatic chamber

- Packaging

- Shipment

The production line

- Screen printerDEK - Horizon 03Ix

- P&PMycronic/Mydata - MY-200lx

- OvenFolungwin - FLW-VP860

- Optical inspectionNordson/Yestech - FX-940

- Selective welding machine PHILLARHOUSE – mod. Sinchrodex

- 2 automatic warehouses Tower Mycronic

- Painting robot PVA

- Automatic ABAG machine for industrial and medical CE safety tests